ST Series

Multi-Axis Laser Processing Machines

These workstations are designed for multi-axis laser welding, heat treating, cladding, drilling and cutting of metallic components.

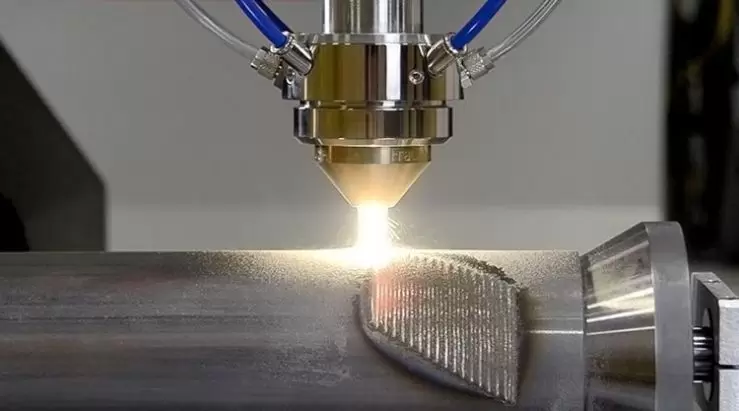

Laser cladding is a process in which material is deposited on the surface of a part or workpiece. The laser cladding process is ideally suited for and is often used to create an entirely new surface, as well as to repair damaged on worn surfaces (remanufacturing). It is even possible to create functionally graded coatings where the material composition of the coating can be changed on the fly, resulting in material properties tailored to particular areas of components.

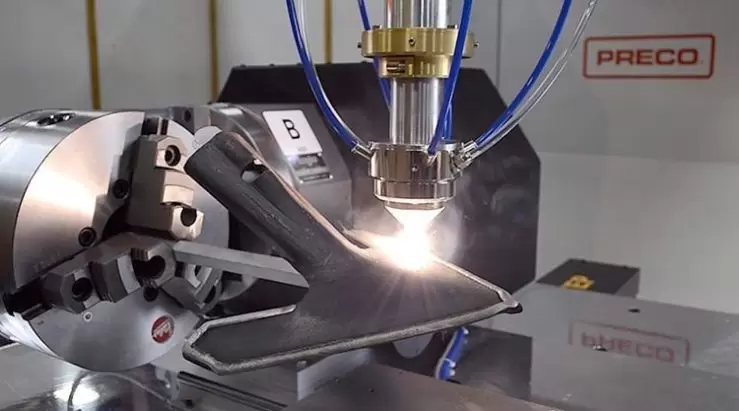

High-speed processing.

Preco's high-speed laser cladding in multiple areas on a machined component. Offering wear resistance through additive manufacturing.

Typically, a powder is introduced to a substrate, and then a laser beam is used to melt the powder onto the substrate. The clad material may also be introduced in a wire form. The process produces a 100% dense metallurgical bond deposit with minimal dilution of the base material for enhanced corrosion, abrasion, and wear resistance when used to laser-clad metals.

There are many advantages to using our laser cladding equipment and laser cladding contract manufacturing services over standard or traditional weld cladding or hard facing, including:

Preco has experience in hybrid and induction-assisted laser welding as well as cold wire feed welding, sometimes necessary if the weld chemistry requires an alteration in order to meet design requirements. More info is available on our laser welding systems, including the SL Series, ST Series, and RT Series. Contact us today to find out if laser welding is an ideal option for your material processing needs.

These workstations are designed for multi-axis laser welding, heat treating, cladding, drilling and cutting of metallic components.

The SL Series is manufactured from standard parts and integrated into a single workstation designed to fit specific customer needs.

Designed for precision laser cutting of small diameter tubes for medical devices such as surgical instruments and implantable devices.