RCP

Rotary Converting Platform

The need for the highest yields and production rates calls for rotary die cutting that delivers flexibility and speed.

Whether you are a contract converter requiring a fast set-up, flexible configuration system, or a manufacturer requiring an engineered solution for your specific rotary converting needs, Preco has a solution. Preco can guide you to the correct configuration by offering the models below. These models have the quickest build times (many stocked components), mechanical and software inspection reports to guaranteeing quality, and qualified installation service once the machine is installed in your plant.

We offer remote access assistance and troubleshooting technical support no matter your location. Preco has been building rotary machines for over a decade with new innovations continually developing.

Maximum flexibility and reliability.

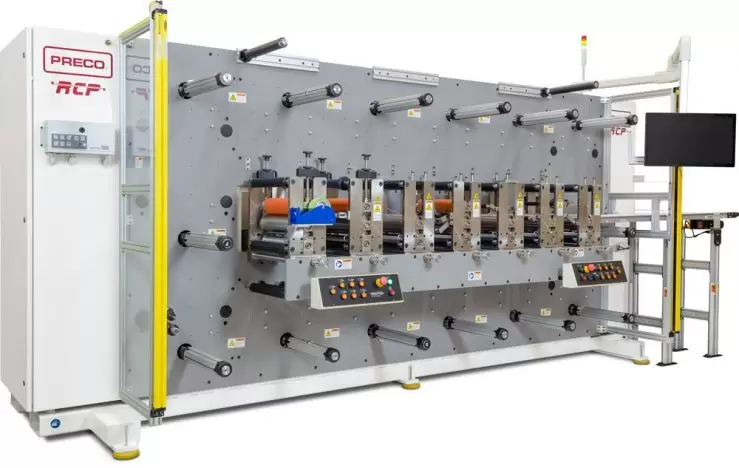

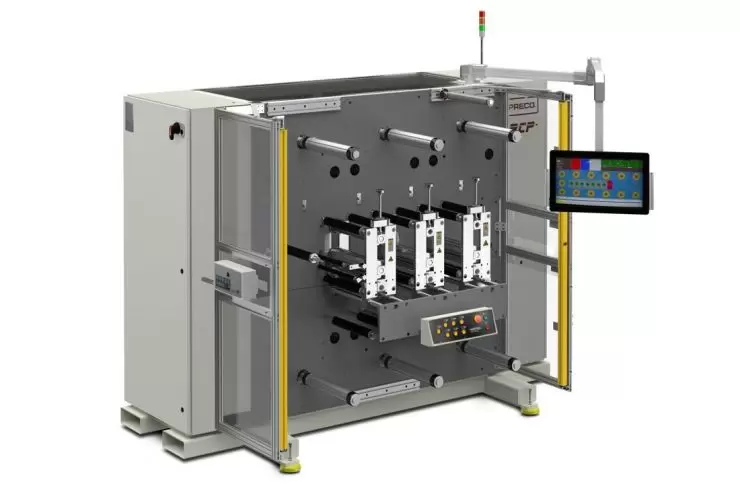

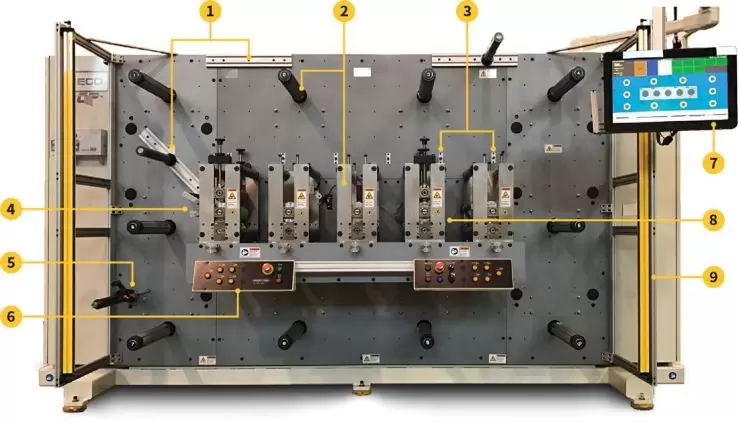

Every Preco RCP machine uses well-organized cabinets for electronics and drives components, which are located as end-caps on the systems. This helps to provide a slim profile for machine placement and ease of serviceability. Spindle motor and reducers via electronic gearing facilitate web and taper influences for precision web tension control. The quick-change modular manifold design allows for maximum setup flexibility using die stations that can be combined or removed for space allocation.

This entry-level rotary offers full functionality and auto-registration for various converting processes. Multi-pass processing possible.

Our intermediate-level rotary offers full functionality and auto-registration for converting processes. Allowing multiple die cutting, lamination and delamination all in a single or multi-pass configuration.

The advanced-level rotary offers full functionality and auto-registration for converting flexibility. Allowing multiple die cutting, lamination and delamination all in a single pass or multi-pass configuration.

Custom equipment is our standard.

The RCP equipment is designed to modularly integrate sub-supplier equipment and functionality. The rotary unit can be expanded or divided into sub-sections to allow specialized automation to occur within a "step and repeat" or "continuous" motion environment for accurate and repeatable insertion or deposition of such components.

Preco will build the exact width machine and type of gearing required for your legacy products to ensure tooling transformation from obsolete equipment into state-of-the-art equipment. Our customized rotary designs are driven by your equipment specification and product drawings from which the overall concept is generated. 3D modeling allows for process and design corrections during the design review phase prior to part/component machining. Debug of your machine takes place on our factory floor until satisfactory results are accomplished.

Add either a Preco-made device from our available options, or construct your own proprietary innovation to create a last-minute, special purpose appliance.

Preco-Built Delivery Conveyor

Tapped Station Mounts

Window Waste Transfer Device

Part Transfer System

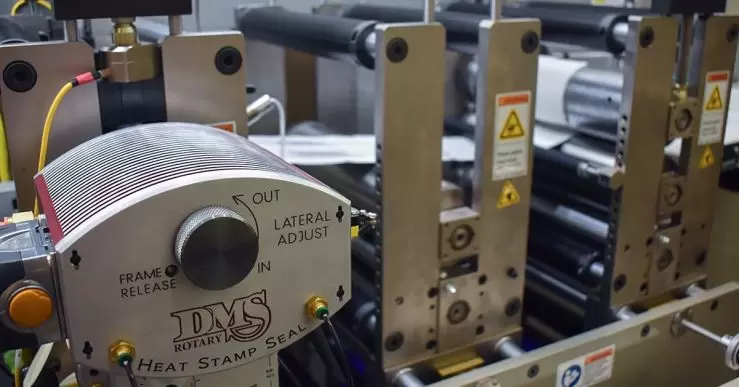

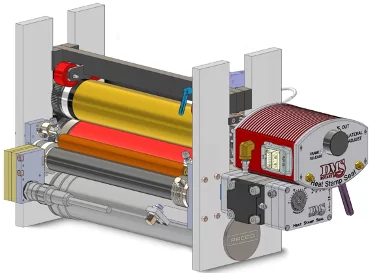

Heat-sealing solutions.

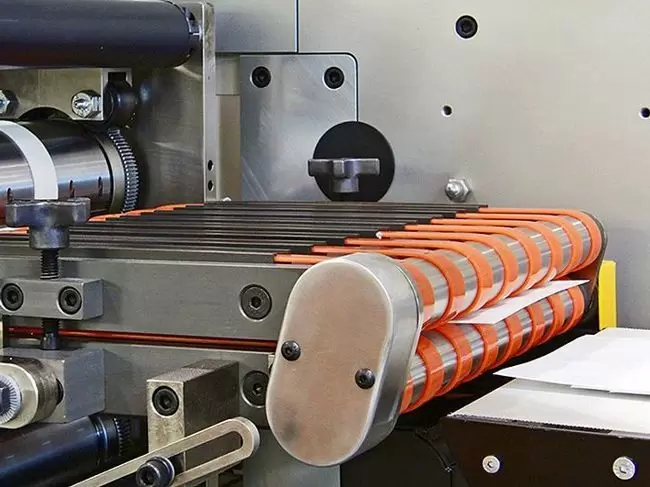

This heat-sealing unit allows easy job changeovers with an interchangeable sleeve of your seal pattern. It is as simple as removing the gear and pattern sleeve and replacing it with your next part sleeve. Changeovers can be done with 15 minutes and you're right back into production. There is also the option to produce three-sided pouches for manually filling product that requires further component insertion.

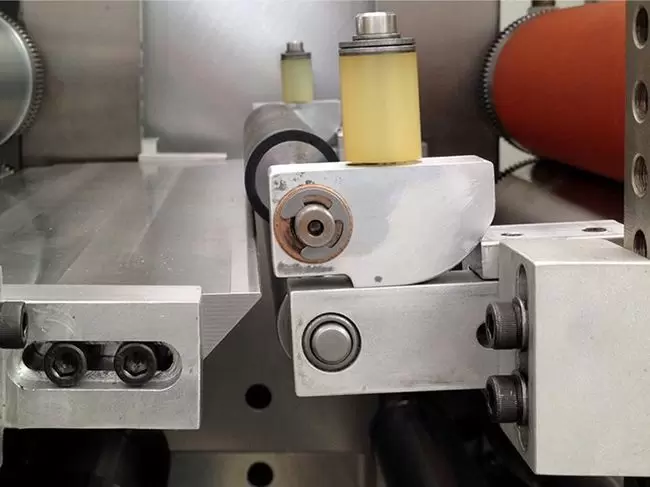

This heat-sealing module can achieve temperatures up to 450° Fahrenheit (232°C) with the steel pattern tool. This module also utilizes a heat-sink material around the cylinder to ensure the heat-affected zone remains in the sealed areas. The impression roller is normally a 75-durometer silicone or Hypalon structure for high-temperature seal reliability and conformity to your materials. An optional torque-kit can be added to monitor load force to ensure the sealing tool does not deviate its compression force during operation. An Infrared feedback sensor is used to closely monitor set temperature and maintain accurate seal temperatures for your qualified process.

A secondary heat source can be added to improve sealing effectiveness and achieve faster run rates for your process. An aluminum roller is added to the inbound station which can be heated up to a maximum temperature of 350° Fahrenheit (176°C). Heat is transferred to a 40-durometer silicone roller that transfers the heat to the impression roller. This creates a dual heating application to improve your seal quality thereby generating less waste. The additional heat also allows for faster production rates. The process may wrap the web around the aluminum roller to act as a preheating mechanism offering viable alternative web paths.

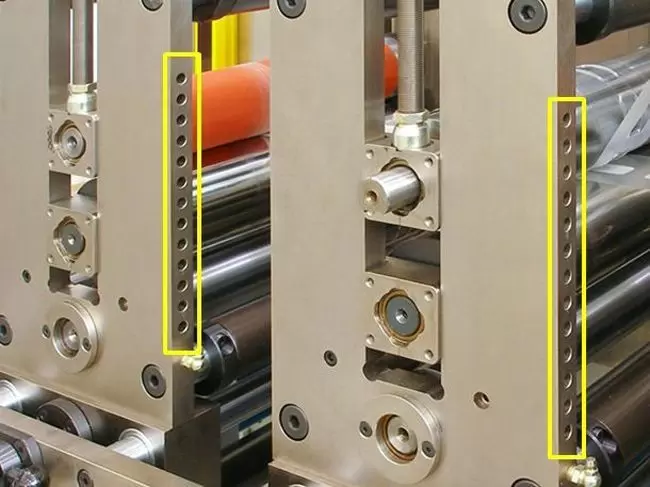

The purpose of an idler roller is to change the direction of a web. Preco's backplane system provides idler roller capability almost anywhere on the platform. The tapped and threaded grid wall allows easy roller placement for processing of materials and for greater efficiency.

Preco found that press operators most often run out of available spindles before using up the process stations. Preco maintains an abundance of capacity.

Electrical connection points on the backplane keep wires out of the path of tooling, materials and the light curtain field. Preco's proprietary registration setup needs only the gear tooth and pattern count with a repeating mark on the web—forget homing devices or extra wires!

Long-Medium-Flush articulated idler rollers give the operator full placement control, whether close or away from the die or nip, upon entering or leaving a process station. Threaded holes on the station ensure a parallel path.

The Preco web guide alignment device provides a simple method for managing of incoming material. Three adjustments are used to assure a correct web approach angle and the equal distance of the web between the send and receive points. A fine-tune screw permits a subtle shift of the web in the Y-axis.

Machine access during setup has been made easy. There is no need to step away to the HMI to lock down a material core, as every spindle is within reach. Apart from setup jog mode, machine speed during production can be increased with a simple turn of a knob.

Whether you are a first-time user or an experienced technician, the HMI touch-screen controls of the RCP are logical and understandable. All components can be entered and monitored, along with ongoing trending of registration accuracy and roll material status.

You may attach a Preco-made device, or better still, an appliance that your company has created for a special purpose. The same M6 threaded holes that mount station idlers are perfect for rapid fastening of just about any fixture that is required for that next work order.

Safety is important, but its implementation should not be an obstacle to required process adjustments. Preco provides the simplest, non-invasive solution.

Preco's Rotary Converting Platform standard sizes and weights.

| Small 3 Stations / 6 Spindles |

Medium 5 Stations / 10 Spindles |

Large 7 Stations / 14 Spindles |

|

| Footprint | Width: 96" (2.4 m) | Width: 154" (3.9 m) | Width: 178" (4.5 m) |

| Height: 90" (2.3 m) | Height: 90" (2.3 m) | Height: 90" (2.3 m) | |

| Depth: 70" (1.8 m) | Depth: 70" (1.8 m) | Depth: 70" (1.8 m) | |

| Approx. Weight | 2 tons (1.8 metric tons) | 3.2 tons (2.9 metric tons) | 4.5 tons (4.1 metric tons) |

| Electrical | US: 480 V, Intl: 400 V 60 A / 50-60 Hz / 3P |

US: 480 V, Intl: 400 V 100 A / 50-60 Hz / 3P |

US: 480 V, Intl: 400 V 150 A / 50-60 Hz / 3P |

| Pneumatics | 90 psi @ 4 SCFM (0.95 bar/min) | 90 psi @ 5 SCFM (1.2 bar/min) | 90 psi @ 6 SCFM (1.4 bar/min) |

| Small 3 Stations / 6 Spindles |

Medium 5 Stations / 10 Spindles |

Large 7 Stations / 14 Spindles |

|

| Footprint | Width: 170" (4.3 m) | Width: 192" (4.9 m) | Width: 210" (5.3 m) |

| Height: 100" (2.5 m) | Height: 100" (2.5 m) | Height: 100" (2.5 m) | |

| Depth: 77" (2 m) | Depth: 77" (2 m) | Depth: 77" (2 m) | |

| Approx. Weight | 3 tons (2.7 metric tons) | 4.8 tons (4.4 metric tons) | 6.8 tons (6.1 metric tons) |

| Electrical | US: 480 V, Intl: 400 V 80 A / 50-60 Hz / 3P |

US: 480 V, Intl: 400 V 150 A / 50-60 Hz / 3P |

US: 480 V, Intl: 400 V 200 A / 50-60 Hz / 3P |

| Pneumatics | 90 psi @ 5 SCFM (0.95 bar/min) | 90 psi @ 8 SCFM (1.2 bar/min) | 90 psi @ 8 SCFM (1.4 bar/min) |

Technical parameters are based on a baseline standard but all Preco rotary machines can be customized to meet your product's needs.

| Press Speed | 0-90 m/min (0-300 ft./min) |

| Standard Web Widths Available | 178 mm (7 in.), 255 mm (10 in.), 330 mm (13 in.), 406 mm (16 in.), 508 mm (20 in.), 609 mm (24 in.) |

| Spindle Servo-Motors: Tension Control Ranges |

Small: 1 – 9 N (0.2 – 2.1 lbf) Large: 11 – 62.3 N (2.5 – 14 lbf) X-Large: 20 – 89 N (4.5 – 20 lbf) XX-Large: 45 – 125 N (10 – 28 lbf) |

| Manual Y-adjustment of Die Stations | ± 19 mm (0.75 in.) travel |

| Servo Stations | Independently driven and controlled |

| Gearing | 1/8 in. pitch, 20° pressure angle, internal attachment to cylinder, (3 mm) pitch optional |

| Automatic Web-Guiding | Ultra-sonic sensing guided positional control Available on any spindle locale, unwind/rewind 0.25 mm (± 0.01 in.) |

| Standard Max Roll Diameter | 508 mm (20 in.) Custom diameter available up to 1.5 m (60 in.) |

| Standard Core Diameters | 76 mm (3 in.), 152 mm (6 in.) |

| RCP Shutdown Mechanisms | Full roll diameter (rewind) Low roll diameter (unwind) Part counter Meterage counter Splice detection |

| Light Curtain Protection | 2 m (6.5 in.), Programmable blanking of zones, discreet units per station available |

| Construction | Welded steel frame with precision-ground, powder-coated Al backplane |

| Shingling/Batching Conveyors | Laser sensor for counting products: 482 mm (19 in.) range Lengths: 0.61 m (2 in.), 1.22 m (4 in.), 1.83 m (6 in.), 2.44 m (8 in.), 3.05 m (10 in.), 3.66 m (12in.) |

The need for the highest yields and production rates calls for rotary die cutting that delivers flexibility and speed.

The need for the highest yields and production rates calls for rotary die cutting that delivers flexibility and speed.

Reach out to a Preco sales representative directly to get your project started.