Material processing solutions.

No matter what market you specialize in, Preco has got you covered. With over 40 years of experience, a multitude of resources and the capability of providing solutions unlike any other manufacturer in the industry, Preco can partner with you to solve your flat bed, rotary and laser-based material processing needs. Here are just a few of the materials we commonly die cut and laser process.

Coated Abrasives

From heavy grit to micro-polishing

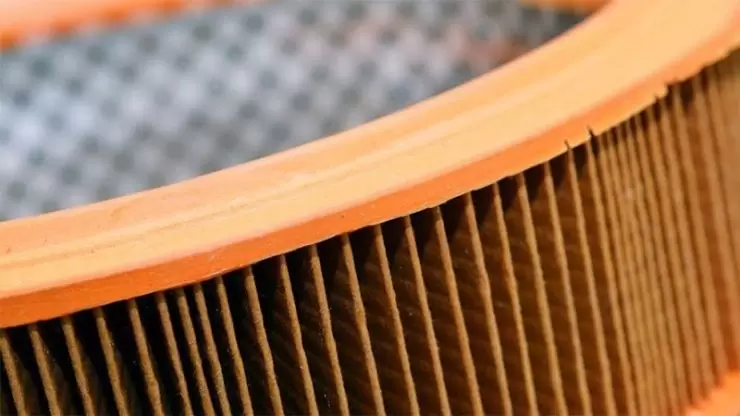

Filters

Cut, collate and stack

Foams

Open-cell, closed-cell and reticulated

Gaskets

Everything from rubber to steel

Magnetic Media

From cutting to laminating

Pressure Sensitive Adhesives

PSA cutting and kiss-cutting

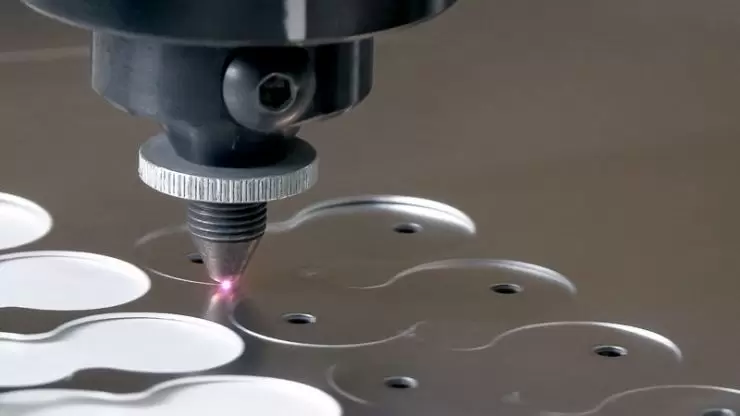

Metals

Alloys, wrought and cast