Trusted Solutions

Preco's Medical Contract Manufacturing Services can provide you with all of the resources needed to integrate laser processing and die cutting into your manufacturing stream. The extensive design, testing and manufacturing capabilities of Preco can help you answer today's challenges – enhancing product design, improving quality, lowering unit cost and shortening lead times.

PRECO IS A PROUD

A big facility with big possibilities.

With over 25 years of Medical Contract Manufacturing experience and a facility with over 40 workstations, Preco has the knowledge and equipment to process your product.

Though every industry and project presents its own unique challenges and design needs, our broad range of experience allows us to tailor a creative solution to your product requirements.

Capabilities

- White Room Processing

- Medical Packaging

- Surgical Tool Fabrication

- Quality Testing

- 40+ Workstations

- Orthopedic Devices

- Stainless & Polymer Tube Processing

- Assembly

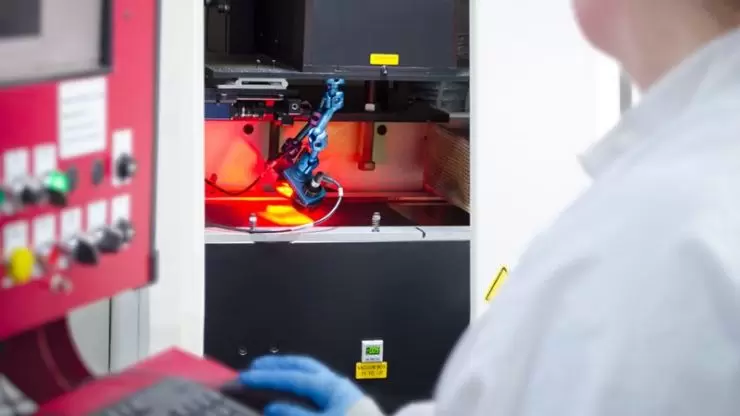

Laser Processing

Preco's contract manufacturing services offer multiple laser processing solutions for your medical applications. Our dedicated staff is capable of handling anything from surgical tool fabrication to converting medical packaging material.

Medical Contract Services Offered

- Ultrafast Laser Processing (Picosecond, Femtosecond)

- Laser Cutting

- Laser Kiss-Cutting

- Laser Welding

- Laser Ablation

Rotary & Flat Bed Die Cutting

Complementing the laser converting offering, Preco's Contract Manufacturing Services also provides a complete range of die cutting solutions. Precision flat bed die cutting with vision registration capabilities for both sheet and roll processing is available along with multiple station rotary die cutting for high productivity, lamination and rotary die cutting.

Medical Contract Services Offered

- Laminating

- Platen Heat Sealing

- Die Cutting

- Kiss-Cutting

- Multiple Roll & Sheet Inputs

- Embossing

Have Questions? Contact Us

Reach out to a Preco sales representative directly to get your project started.

Mark Daun

Craig Swanson