Clean and accurate cuts.

Designed and built for the foam die cutting and converting industry. Die cutters need systems that provide a clean and accurate cut part that reduces concavity in the processing. The benefit is more precision—part-to-part accuracy and tighter tolerances of parts cut.

Standard Flatbed Press Sizes

| Model | Working Width | Feed Direction Length | Cutting Force |

| 1220 | 20" (510 mm) | 12" (305 mm) | 40 tons |

| 2024 | 24" (610 mm) | 20" (508 mm) | 40 or 60 tons |

| 2430 | 30" (762 mm) | 24" (610 mm) | 40 or 60 tons |

Larger press sizes also available

Options & Capabilities

- 6 to 60 inches wide

- 1/16 to 4 inches thick

- Through-cutting

- Count and stack or shingle parts

- Stacking/conveying

- Kiss-cutting to liner

- Heat sealing

- Industrial applications

- Medical components

Features & Benefits

- Ultra-accurate kiss-cut

- micrometer stop

- Quick change steel rule

die clamps - Microprocessor controlled

touch panel display

- Robust four-post press design

- Precision controlled hydraulics

- Precise roll-feed material drives

- Variable material & toll stroke length adjustment

EDP-W Automated Traveling Head Die Cutter

| Model | Working Width | Feed Direction Length | Cutting Force |

| EDP-W-1650 | 64.96" (1650 mm) | 23.6" (600mm) | 27.56 tons |

| EDP-W-2050 | 80.71" (2050 mm) | 23.6" (508 mm) | 27.56 tons |

Cutting forces of 49.6 tons and 66.14 tons

(45 and 60 tonnes) also available.

Options & Capabilities

- Different cutting tonnage

- Cutting head rotating on its

axis 180° - Automatic die change

- Unwinders for jumbo rolls

- Automatic stacking system

- Waste winder

Features & Benefits

- Fully electrical machine, no hydraulic systems involved

- Material feed system via pinch and grab bar and motorized conveyer

- Punching system mounted on traveling head covering the whole board width

- Able to cut multiple web layers at the same time

- Head displacement by servo motor for accurate cutting tool position

- Slug holes are automatically collected and vacuumed away from the cutting tool

- Cutting against dedicated conveyor belt or on counter board. Board oscillates on the X-Y axis

- A dedicated Software manages the whole process and a touch screen allows the operator to change all the settings.

- Control software is organized into recipes, easy to recall

- The touch screen gives the possibility to optimize the position of the cutting footprints so as to minimize waste material as much as possible.

Silicone Sponge PU Foam Open Cell Sponge Rubber PVC Foam PE Foam PS Foam

Get in touch today to learn how we can help you with your foam die cutting needs.

Watch to Learn More

Features and Options of Preco's Die Cut Press Systems

Preco's Foam Die Cutting Features & Options

Biko's EDP-W CNC Traveling Head Die-Cutting Press

Have Questions? Contact Us

Reach out to a Preco sales representative directly to get your project started.

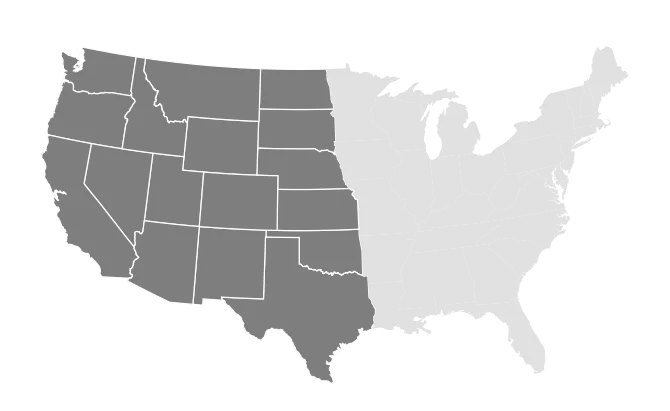

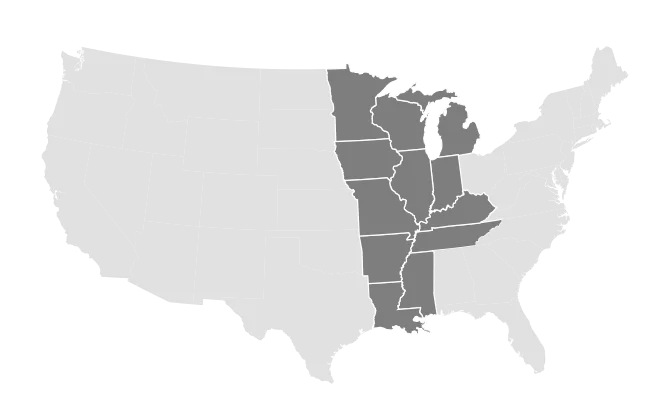

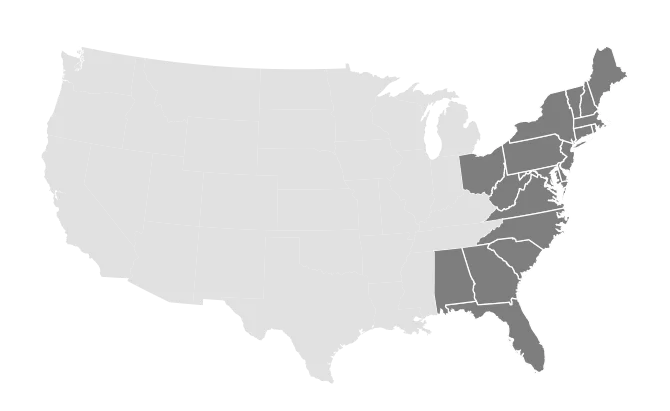

Luke Burns

Darren Evans