Micro Solutions

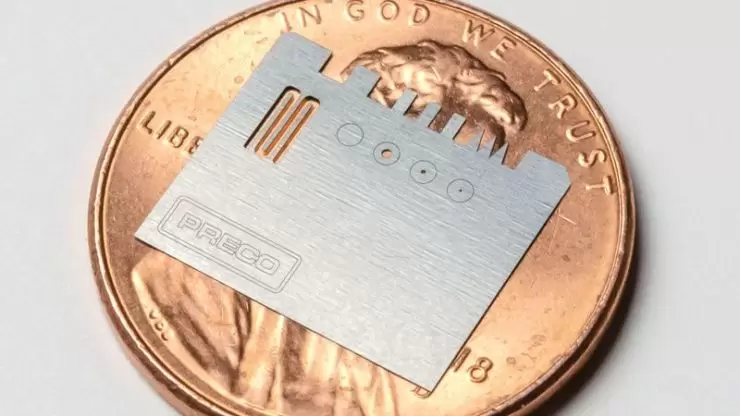

Femtosecond lasers allow companies to produce small features such as holes and slots, with single-digit micron resolution in medical devices such as surgical tools, aids, and implantable devices, with clean, burr-free edges and features with virtually no heat-induced distortion. High-power, small spot size fiber lasers, coupled with high-speed scan heads, can cut thin metals for various applications at speeds that match or exceed traditional hard-tool production rates.

Applications

- Microfluidics

- AIVs

- Medical Applications

- Biospy Equipment

- Filters

- Functional Surfaces

- Infrared Sensors for Cameras

- Memory Chips

- Solar Cell Production

- Semiconductor Industry

- Waveguides

Picosecond and Femtosecond Pulses

Picosecond and femtosecond ultrafast lasers produce predictable, repeatable textures on implant surfaces, with improved location accuracy making them ideal for the production of medical devices. Ultrafast laser equipment and processing services can also be used to create microgrooves and other types of micro-texturing in molds for injection-molded parts.

MATERIALS

- Glass

- Steel

- Ceramics

- Silicon

- Stainless Steel

INDUSTRIES

- Medical

- Electronics

- Energy

- Industrial

- Automotive