FlexPro

Multi-Purpose Laser Machine

The FlexPro® laser system provides the speed of galvanometer processing with the versatility of an XY motion system.

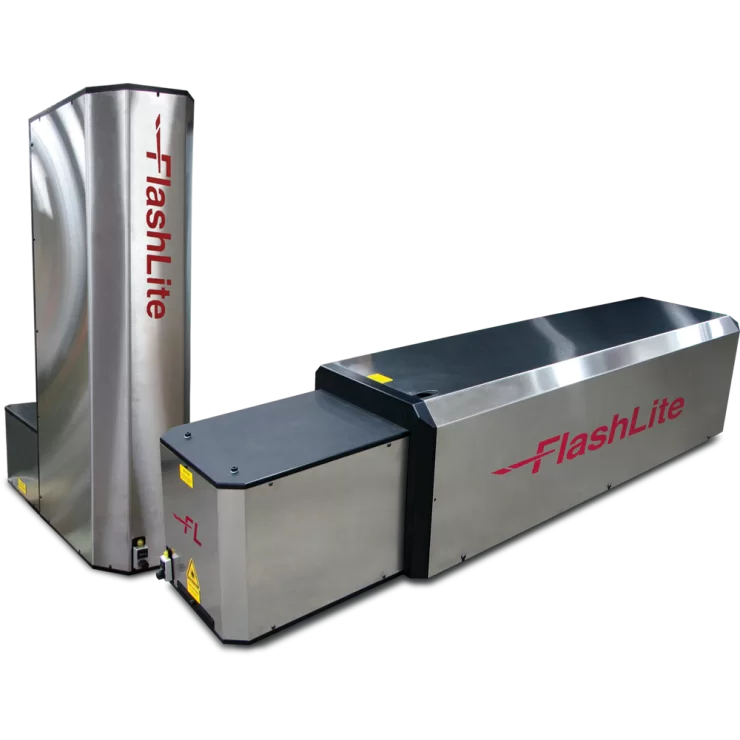

This compact and economical version of the Preco high-speed "directed beam" technology provides laser processing for numerous applications. Preco's FlashLite™ G Series laser module is all you need if you already have material handling in place.

Cost-effective in a complete package.

This compact processing module is a cost-effective, complete laser package that can be added to virtually any web or sheet handling line. Laser processing is typically on the fly or in a step and repeat manner. Laser triggering is based on distance, eye mark triggering or vision registration.

Preco's FlashLite modules are configured to meet your needs; single or multiple modules are available with various laser types and power levels. To provide the best fit for your production line, this module can be configured to mount vertically or horizontally.

Just some of the many benefits of buying a Preco laser module.

Provides uniform scoring independent of shape and processing speeds

Reduces set-up time; consistent production from operator to operator

Small footprint allows the module to be used virtually anywhere – from prototyping labs to production facilities

Increased margins; High throughput and low operating costs

Eliminates inconsistencies of knives and other mechanical methods

Easy to use Windows® based software enable make-to-order processing of short-run or complex jobs

Allows for optimized cut speed and cut quality from one job to the next

I/O available for seamless interface to the existing production line or material handler

Precision control of laser energy, unique to Preco

Technical parameters are based on a baseline standard but all Preco laser machines can be customized to meet your product's needs

| FL-G 100 | FL-G 200 | FL-G 300 | FL-G 400 |

|

Process Capabilities

|

| Laser Wavelength (µm) | 9.4 | 10.2 | 10.6 | 9.4 | 10.2 | 10.6 | 9.4 | 10.2 | 10.6 | 9.4 | 10.2 | 10.6 |

| CW Power Range (rated W) | 5-80 | 5-100 | 5-100 | 5-150 | 5-160 | 5-200 | 10-225 | 10-240 | 10-300 | 40-400 | ||

| Percentage of Power Stability | < ± 2 - 5 | < ± 5 - 7 | < ± 5 - 7 | < ± 5 - 7 | ||||||||

| Chiller Requirements | 2-kW, 7.5-l/min @ 20 °C | 5-kW, 6-l/min @ 20 °C | 7-kW, 6-l/min @ 20 °C | 8-kW, 7-l/min @ 20 °C | ||||||||

|

Electrical Requirements

|

| Voltage | 200 - 230 VAC | 200 - 230 VAC | US: 200 - 230 VAC Int: 380 - 420 VAC |

US: 200 - 230 VAC Int: 380 - 420 VAC |

| Phase | 1 | 1 or 3 | 3 | 3 |

| Hertz | 50/60 Hz | 50/60 Hz | US: 60 Hz Int: 50 Hz |

US: 60 Hz Int: 50 Hz |

|

Environmental Requirements

|

| Temperature | 18 - 27° C (65 - 80° F) | |||

| Altitude | 2,000 meters (1.2 miles) | |||

| Humidity | < 95% non-condensing | |||

The above data is subject to change. All specifications are dependent on laser power, material type and thickness, and process platform - consult with a Preco associate.

* Laser Chiller may be powered separate or by laser system.

The FlexPro® laser system provides the speed of galvanometer processing with the versatility of an XY motion system.

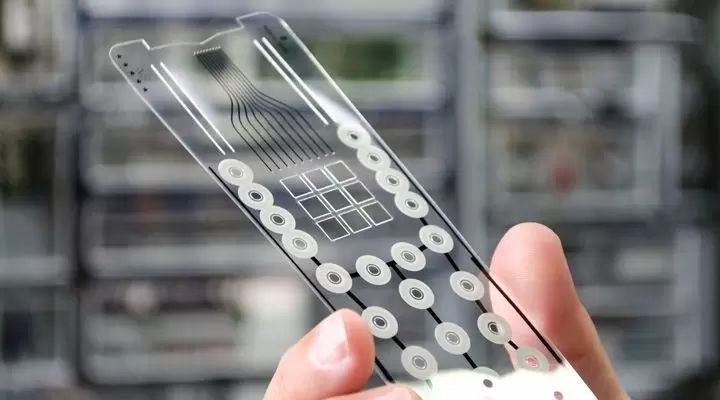

The Mini FlexPro® laser processing system offers innovative solutions for high-speed laser processing of flexible circuits.

The WebPro Series of digital laser cutting systems are rapidly re-configured for changing job requirements.

The Wide WebPro Series is a wide web-based, traveling head laser systems for roll-to-roll or roll-to-discrete part processing.

FlashLite G Modules provide high-speed, laser processing for through cutting, kiss-cutting and perforating.

Reach out to a Preco sales representative directly to get your project started.