Flat Bed Die Cutter

Four-Post Hydraulic Flat Bed Press

Our four-post flat bed hydraulic press is our standard flat bed die cutting system and is available in a variety of platen sizes.

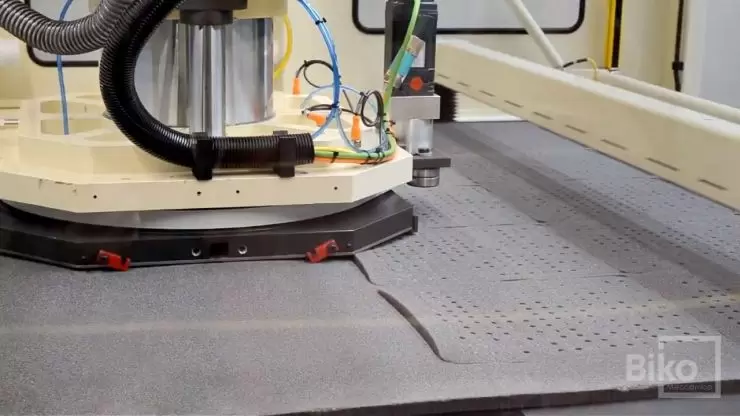

The EDP-W automated traveling head system represents the highest automated system which allows converters to die cut various types of materials and desired shapes. The feeding of material is automatic and is managed by a transportation conveyor running together with a pinch and grab system.

Wide range of possibilities.

This machine can handle materials with a wide range of weights and different thicknesses which can be processed in multiple layers. The EDP-W has a wide range of configurable cutting forces and cutting head surfaces allowing converters to take on a wide range of applications.

Learn more about Preco's foam die cutting machines designed and built for the foam die cutting and converting industry.

Slug holes are automatically collected and vacuumed away from the cutting tool.

Just some of the many benefits of buying an EDP-W Automated Traveling Head Die Cutter.

No hydraulic system involved

Cutting against dedicated conveyor belt or on counter board

Manages the whole process and a touch screen allows the operator to change all settings

Organizes recipes and is easy to recall

Capable of cutting more than one web layer at the same time

Gives the possibility to optimize the position of the cutting footprints so as to minimize waste material as much as possible

Via pinch and grab bar with motorized conveyor

Mounted on traveling head covering the whole board width

Head displacement by servo motor for accurate cutting tool position

Technical parameters are based on a baseline standard but all EDP-W Automated Traveling Head Die Cutting systems can be customized to meet your product's needs.

| EDP-W-1650 | EDP-W-2050 | |

| Machine Dimensions | Length: 5287 mm (17 ft. 4 in.) | Length: 5287 mm (17 ft. 4 in.) |

| Width: 4165.5 mm (13 ft. 8 in.) | Width: 4565.5 mm (15 ft.) | |

| Height: 2902 mm (9 ft. 6 in.) | Height: 2902 (9 ft. 6in.) | |

| Machine Weight | 9,000 kg (9.92 tons) | 10,500 kg (11.57 tons) |

| Material Widths | 1650 mm (64.96 in.) | 2050 mm (80.71 in.) |

| Installed Power | 18 kW | |

| Air Consumption | 200 NI/h | |

| Cutting Force | 25 tonnes (27.56 tons) (45 and 60 tonnes available(49.6 tons and 66.14 tons)) | |

| Cutting Tool Mounting Board | 600 x 600 mm (23.62 x 23.62 in.) (1000 x 1000 mm (39.37 x 39.37 in.) also available) | |

Our four-post flat bed hydraulic press is our standard flat bed die cutting system and is available in a variety of platen sizes.

This four-post flat bed system has flexible optics that you can select from X, X–Y, X-Y-θ options to assure consistent optical registration.

This electromechanical machine is designed primarily for die cutting components in a clean environment.

Servo-driven traveling head press represents the highest automated system allowing converters to die cut various materials and shapes.

Reach out to a Preco sales representative directly to get your project started.