How Preco Can Help

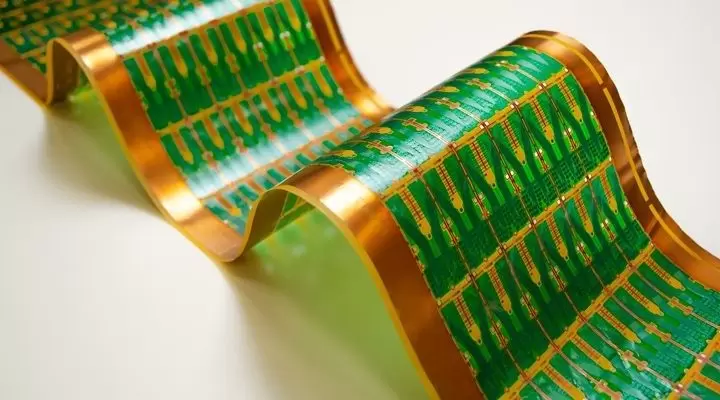

Preco die cutting solutions are often designed with the intention to provide exacting singulation of multiple-up circuit arrays on the one hand, and for the application of etch resists, additive conductive traces, insulators and masks and legend, to a variety of flexible circuit and membrane switch substrates. We employ vision-based systems for close-tolerance processing to deliver reliability to row, column and part.

Planning critical milestones.

Preco gets deeply involved with the front-end planning that goes into achieving critical milestones throughout design, testing, prototyping, and production. Proactive project management and ongoing quality assurance reporting ensure that we can quickly address any issues related to material quality, processing, or logistical concerns. This high level of “hassle-free” support and accountability helps you maintain flexibility when unforeseen challenges arise.

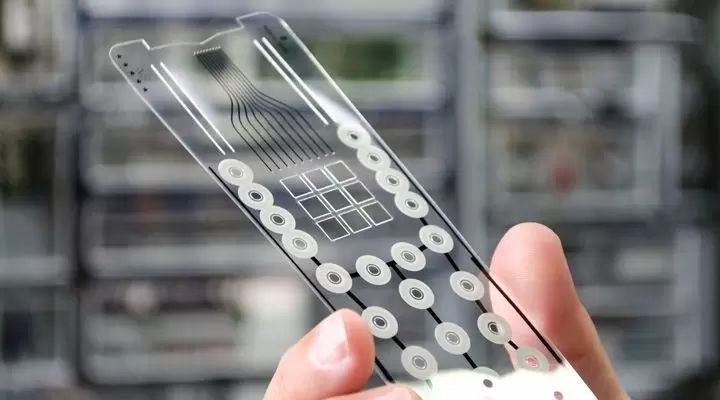

Flexible Circuits and Membrane Switches

Simpler and more reliable electronic interconnections are possible with flex circuits and membrane switches, and tight tolerances and fine-line circuits are an important benefit. Because of these properties, flex circuits and membrane switches require accuracy in cutting. Preco has the unique and distinct advantage of offering a variety of solutions for processing flex circuits. Preco has die cutters and precision laser processing systems to process flex circuits and membrane switches.

Materials

- Polyamide Films

- Polyesters

- Kapton® Film

- Mylar® Film

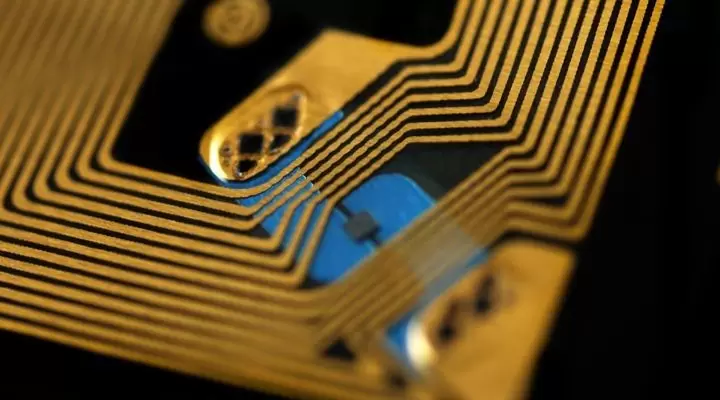

Radio Frequency Identification (RFID)

Antenna production is as varied in its manufacture as the general flexible circuitry field. It is no wonder that solutions for making everything under the sun are equally diverse.

Preco provides a unique variety of tools for producing antennas, fine-tuning the circuit, slitting, singulating, scoring, insulating, laminating, quality control and other finishing requirements.

Materials

- Plastics (PET, PEN, PP, PI, PVC, PMMA, PC, ABS, etc.)

- Paper (Coated Label Stock)

Preco Solutions

| Application | Expertise |

| LF, HF, UHF, microwave types | Systems strategies for all frequencies |

| Imaging format widths | As wide as 650 mm, depending on the method |

| Antenna length | Formats from 6 mm to 3 meters (or greater) are not only possible but welcome. |

| Trace or line width | Typical to 100 µm, but consistently achievable to 50 µm |

| Solder paste / conductive adhesive application | Either by screen or stencil plate |

| Testing | 100% inspection systems available for our products |

| Antenna/process circuit combination | Producible and individually treatable in one format; promotes the inclusion of displays, readouts, active onboard batteries, etc. |

| Web image consistency | Assures indexed alignment, as well as a constant index pitch for down-line vision requirements for chip, attach, etc. |

| Physical laser trim of antenna length | Quick, mass-production technique for uniformity to discourage attenuation. |

| Packaging | Mass-produced webs made into smaller rolls; systems for integrated, JIT variable information printing for lot personalization. |