FlexPro

Multi-Purpose Laser Machine

The FlexPro® laser system provides the speed of galvanometer processing with the versatility of an XY motion system.

Preco integrates advanced laser technology with reliable equipment, offering innovative and cost-effective solutions for web-based laser cutting, scoring, slitting and kiss-cutting.

The WebPro Series of digital laser cutting systems are rapidly re-configured for changing job requirements and are the ideal match for short-run jobs in all sizes and materials. The AcuBeam™ control system operates in a user-friendly Windows® environment, allowing you to control the entire system. As a result, changeovers are as simple as opening a file without the need or costs of tooling.

Fast speeds with an exclusive design.

This unique system allows you to laser process web widths from 25.4 mm to 610 mm (1 - 24 in.) at high production rates. Our exclusive motion design processes materials at speeds 9.14 m to 60.96 m (30 - 200 ft.) per minute, while maintaining consistent PLI across the entire process. Typical accuracies range ± 0.076 mm to 0.254 mm (0.003 - 0.010 in.) based on part size and geometry.

The WebPro incorporates 200, 300, 400, 600 or 1000 watt CO2 lasers with 9.3 to 10.6 µm wavelengths, as well as UV lasers. These lasers offer a reliable, precise beam that results in clean and sharp laser processed edges.

Just some of the many benefits of buying a Preco WebPro Series laser machine.

Cuts parts from moving webs for maximum production rates

Eliminates tool and die fabrication, maintenance, and storage costs

Registers parts before processing and aligns cut pattern to fiducials - either printed or mold marks. Inspection of parts available after processing for 100% quality control

Enables make-to-order processing of short-run or complex jobs

Eliminates scrap caused by overpowering of material at slower than normal processing speeds

Produces intricate patterns and fine details. Superior part quality that cannot be replicated using the die cut process

Single or dual cameras for X-Y-Θ positioning of the cut pattern to material features

Adjustment of laser power "on-the-fly" based on the beam movement

Reduces set-up time; consistent production from operator to operator

Technical parameters are based on a baseline standard but all Preco WebPro Series laser machines can be customized to meet your product's needs.

| LB3100 | LB3200 | |

|---|---|---|

| System Footprint | Width: 3.2 m (10 ft. 6 in.) | Width: 3.2 m (10 ft. 6 in.) |

| Depth: 1.85 m (6 ft.) | Depth: 2.16 m (7 ft.) | |

| Height: 2.18 m (7 ft. 2 in.) | Height: 2.18 m (7 ft. 2 in.) | |

| Lasers | 1 | 1 – 2 |

| Output Heads | 1 | 1 – 2 |

| Web Width (Nominal) | Standard 305 mm (12 in.) | Standard 610 mm (24 in.) |

| 3-Axis Scan Head | Fixed 305 mm (12 in.) | 1: Adjustable 305 - 610 mm (12 - 24 in.) 2: Fixed 330 mm (13 in.) with 25 mm(1 in) cross-web overlap (13 x 24 in total processing area) |

| Lower Vacuum Work Support | Included (featuring a debris collection bin) | |

| Laser Wavelengths | 9.3 µm, 10.2 µm or 10.6 µm | |

| Safety Enclosure | Class 1 | |

| AcuBeam™ Software | Windows® based with full graphical / CAD interface | |

| Laser Power | 100 – 1,000 Watts (Other laser sizes available per request) | |

| Power Requirements* | Controller & Chiller (Int) : 380-420VAC, 3PH, 50Hz | |

| Controller & Chiller (US): 200-230VAC, 3PH, 60Hz | ||

The above data is subject to change. All specifications are dependent on laser power, material type and thickness, and process platform - consult with a Preco associate.

* Laser Chiller may be powered separately or by the laser system.

The FlexPro® laser system provides the speed of galvanometer processing with the versatility of an XY motion system.

The Mini FlexPro® laser processing system offers innovative solutions for high-speed laser processing of flexible circuits.

The WebPro Series of digital laser cutting systems are rapidly re-configured for changing job requirements.

The Wide WebPro Series is a wide web-based, traveling head laser systems for roll-to-roll or roll-to-discrete part processing.

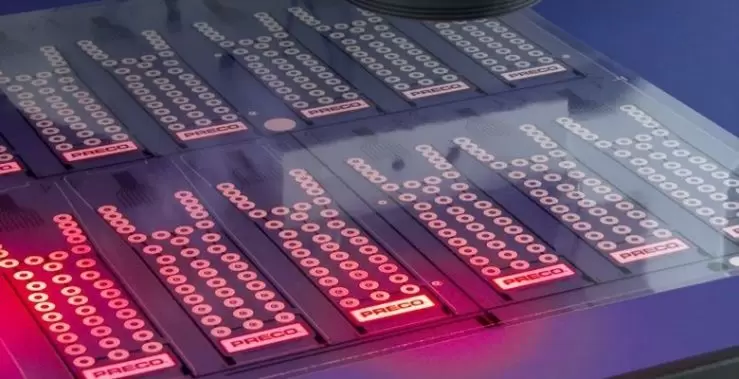

FlashLite G Modules provide high-speed, laser processing for through cutting, kiss-cutting and perforating.

Reach out to a Preco sales representative directly to get your project started.