FlexPro

Multi-Purpose Laser Machine

The FlexPro® laser system provides the speed of galvanometer processing with the versatility of an XY motion system.

Preco's Wide Web-Based laser systems for roll-to-roll or roll-to-discrete part processing. These larger, turnkey systems are ideal for high production requirements. Available in two different widths, the base systems feature reel-to-reel processing with multiple lasers. The control system operates in a user-friendly Windows® environment, allowing both cross-web and simple shape processing. As a result, changeovers are as simple as opening a file without the need of costly tooling.

Jumbo roll capabilities.

The Wide WebPro series of digital laser cutting systems are rapidly re-configured for changing job requirements. This machine has jumbo roll capabilities because of its larger footprint design.

The base systems may include additional features to accommodate inbound lamination, in-line mechanical slitting, loose discs output conveyor, differential rewinding or multiple robotic stacking.

Estimated throughput per laser power level.

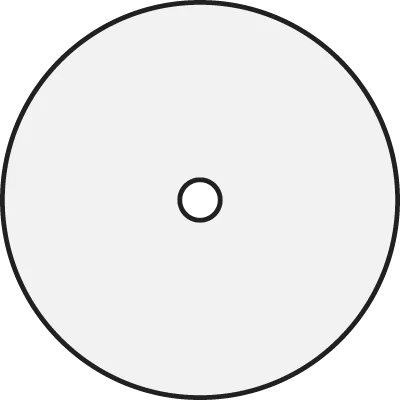

Discs Per Hour

| Grit | 1,000 W | 2,000 W |

| P80 | 3,500 | 4,700 |

| P150 | 5,000 | 6,000 |

| P400 | 5,800 | 6,300 |

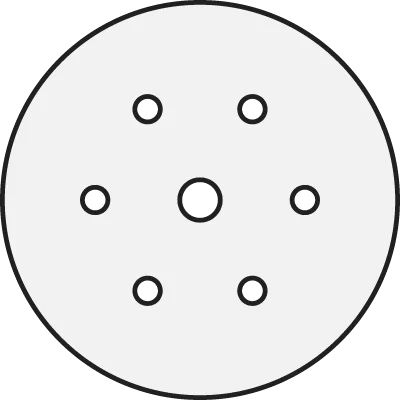

Discs Per Hour

| Grit | 1,000 W | 2,000 W |

| P80 | 2,700 | 3,960 |

| P150 | 4,300 | 5,100 |

| P400 | 5,100 | 5,700 |

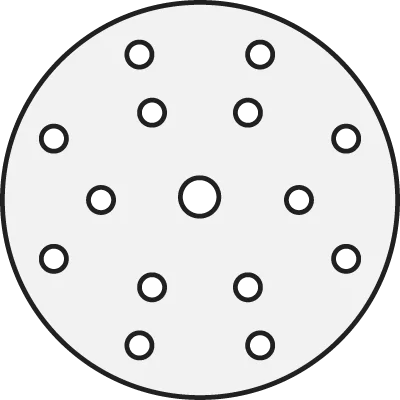

Discs Per Hour

| Grit | 1,000 W | 2,000 W |

| P80 | 2,300 | 3,300 |

| P150 | 3,700 | 4,500 |

| P400 | 4,500 | 5,100 |

Discs Per Hour

| Grit | 1,000 W | 2,000 W |

| P80 | 900 – 1,200 | 1,400 – 1,800 |

| P150 | 1,500 – 2,000 | 2,000 – 2,700 |

| P400 | 2,000 – 2,700 | 2,300 – 3,100 |

Just some of the many benefits of buying a Preco Wide WebPro Series laser machine.

The non-contact process eliminates tool and die fabrication, maintenance and storage costs

Sealed edge and no burrs, slugs, debris or strands left on cutting edge (depending on material)

Multiple fixed beam and galvo configurations with processing speeds up to 38 m (1500 in.)/minute

Allows precise cutting of imperfectly positioned materials or compensation for screen stretch

Eliminates scrap caused by the overpowering of material at slower than normal processing speeds

Allows for optimized cut speed and cut quality from one job to the next

Provides consistent processing independent of cut shape and processing speeds

Cut Parts from moving webs for maximum production rates

Reduces set-up time; consistent production from operator to operator

High throughput and low operating cost mean increased margins

I/O available for seamless interface to the existing production line or material handler

Easy to use Windows® based software enable make-to-order processing of short-run or complex jobs

The Wide WebPro Series is available with a variety of options including laminators, rotary die cutters, or multiple stations consisting of both lasers and die cutters.

Web steering, Closed-loop web tensioning or dancers, Pre or post-process lamination, Weed/scrap stripping, Knife Slitting, Discrete part takeaway conveyor, Guillotine Sheeter, 152 mm (6 in.) core air chucks or adapters, Slice detection, Vision QC

Conveyor

Delivers discs from cut zone to operator or robotic stacking workstations

Vision Registration System

Single or dual cameras for X-Y-Θ positioning of the cut pattern to material features

Lower Vacuum Work Support

External filtering or debris separator

Robotics

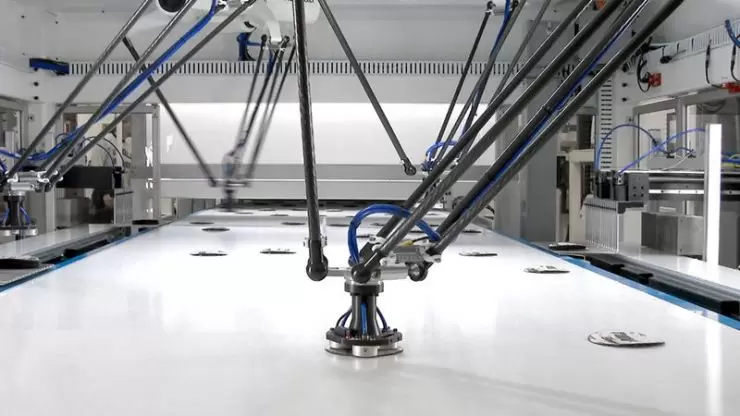

Single or dual spider robots and stacking conveyor

Additional Options

Technical parameters are based on a baseline standard but all Preco Wide WebPro Series laser machines can be customized to meet your product's needs.

| LB3500 | LB4300 | LB4500 | |

|---|---|---|---|

| System Footprint | Length: 15.2 m (50 ft.) | ||

| Width: 8.5 m (28 ft.) | |||

| Height: 2.6 m (8 ft. 6 in.) | |||

| Lasers | 1 | 2 – 3 | 3 – 5 |

| Output Heads | 1 | 2 – 3 | 3 – 5 |

| Web Width (Standard) | 914 mm (3 ft.) | 1.53 m (5 ft.) | |

| Processing Speeds* | Up to 15 m/min (50 ft./min) | Up to 15 m/min (50 ft./min) | |

| Lower Vacuum Work Support | Included, with debris collection | ||

| Laser Power** | 1,000 and 2,500 Watts | ||

| Laser Wavelengths | 9.3 µm, 10.2 µm or 10.6 µm | ||

| Safety Enclosure | Class 1 | ||

| Patented AcuPower™ Control | Adjustment of laser power "on-the-fly" based on the beam movements | ||

| AcuBeam™ Software | Windows® based with full graphical / CAD interface | ||

| Laser Power | 100 – 1,000 Watts (Other laser sizes available per request) | ||

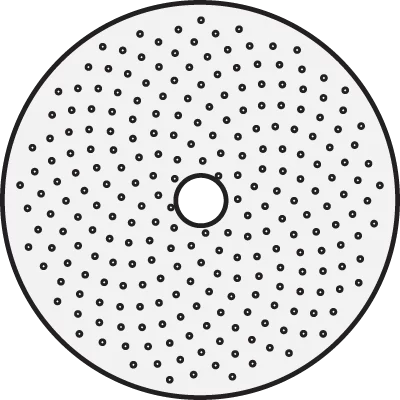

| Abrasive Grits | With holes: 36 grit or higher Without holes: 24 grit or higher |

||

| Power Requirements*** | Controller & Chiller (Int) : 380-420VAC, 3PH, 50Hz | ||

| Controller & Chiller (US): 200-230VAC, 3PH, 60Hz | |||

The above data is subject to change. All specifications are dependent on laser power, material type and thickness, and process platform - consult with a Preco associate.

*Processing speed is dependent on the part size and geometry, laser power, material type and thickness.

**Other laser sizes available per request.

***May be powered separately or by the laser system.

The FlexPro® laser system provides the speed of galvanometer processing with the versatility of an XY motion system.

The Mini FlexPro® laser processing system offers innovative solutions for high-speed laser processing of flexible circuits.

The WebPro Series of digital laser cutting systems are rapidly re-configured for changing job requirements.

The Wide WebPro Series is a wide web-based, traveling head laser systems for roll-to-roll or roll-to-discrete part processing.

FlashLite G Modules provide high-speed, laser processing for through cutting, kiss-cutting and perforating.

Reach out to a Preco sales representative directly to get your project started.