Medical Solutions

Preco's experience, technology and innovation drive our engineering and product processing capabilities. By partnering with us you are able to tap into our manufacturing expertise to reduce costs and improve efficiency when bringing your product to market. We don’t just provide multiple services, we deliver a complete solution.

Medical Equipment Line

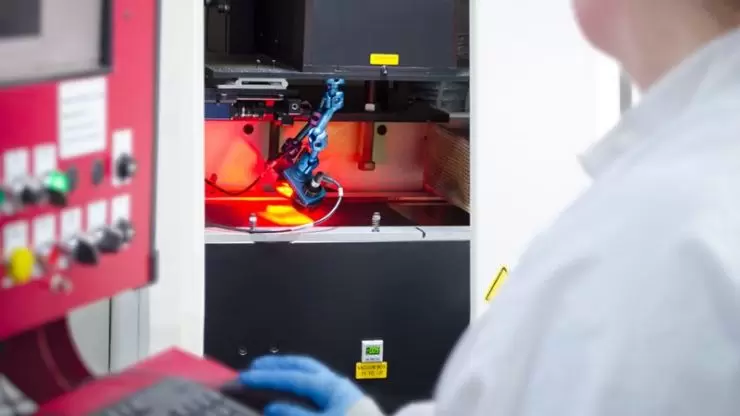

Preco Medical specializes in the manufacturing of laser machines, laminators and flat bed and rotary die cutters ready to process your medical application in a clean environment.

View MachinesMedical Contract Manufacturing

Preco Medical's Contract Manufacturing Services can provide you with all of the resources needed to integrate laser processing, die cutting and laminating into your manufacturing stream.

View Services