Innovative and Cost-Effective

The Micro FlexPro laser processing machine offers innovative and cost-effective solutions for high-speed laser processing of medical device components and flexible circuits.

Applications

- Advanced Wound Care

- Body Sensors & Wearables

- Cosmetics – Hydrogel Face Masks

- Flexible Circuits

- Food Safety Devices

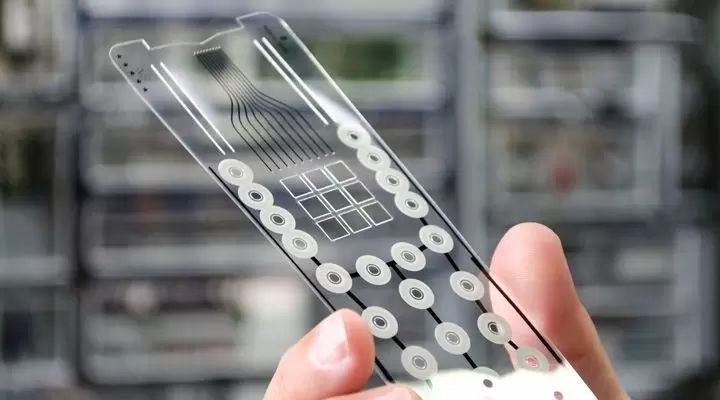

- Microfluidics

- Point-of-care, diagnostic test strips

Speed and Versatility.

The Micro FlexPro laser processing systems are rapidly re-configured for changing job requirements and are the ideal match for short-run jobs in all sizes and materials. The AcuBeam™ control system operates in a user-friendly Windows environment, allowing you to control the entire system. As a result, changeovers are as simple as opening a file without the need or costs of tooling.

Micro FlexPro's non-contact laser process eliminates tool and die fabrication, maintenance and storage costs. This also ensures a superior edge quality with no burrs, debris or strands left on the cutting edge.

MATERIALS

- Acrylic Foam Adhesives

- Hydrogel

- Hydrocolloid

- Non-wovens

- PET

- PLA

- PMMA

- PP, BOPP

- Pressure Sensitive Adhesives

- Silicon Adhesives

CAPABILITIES

- Laser Ablation

- Laser Marking

- Laser Cutting

- Laser Etching

- Laser Kiss-Cutting

- Laser Perforating

- Laser Scoring / Scribing

- Via Drilling (Micro-via)

Features & Benefits

Just some of the many benefits of buying a Preco Micro FlexPro laser machine.

X-Y Table with Galvanometer

Larger sheet and part sizes cut with higher precision and better quality

Preco Patented AcuPower™

Provides uniform processing independent of cut shape and processing speeds

Vision Registration System (Optional)

Single or dual cameras for X-Y-Ø positioning of the cut pattern to material features

Automatic Tiling

Saves programming time because large cut fields are automatically segmented to fit current field-of-view

Job Database

Reduces set-up time; consistent production from operator to operator

Laser Choices

Configured to accept various laser wavelengths and power based on the material to be processed

Fixed 3-Axis Scan Head

Allows for the field of view (FOV) adjustments without changing optics

Automation Choices

Customization options to accept a variety of sheet loaders and unloaders

Roll-to-roll (optional)

Multifunctional option allowing for processing rolls up to 150 mm (6 in.) wide

Tech Specs

Technical parameters are based on a baseline standard but all Preco laser machines can be customized to meet your product's needs.

| Machine Footprint | Width: 914 mm (36 in.) |

| Depth: 2 m (78 in.) | |

| Height: 2.4 m (95 in.) | |

| X-Y stage (Servo Driven) | 305 x 610 mm (12 x 24 in.) |

| Lower Vacuum Work Support | Included |

| Laser Wavelengths | Ultrafast @ 1030 nm IR, 515 nm Green and/or 343 nm UV |

| Safety Enclosure | Class 1 |

| AcuBeam™ Software | Windows® based with full graphical / CAD interface |

| Password Protection | 2-Levels: Administrator & Operator |

| Laser Power | (Laser sizes to be determined by application) |

| Power Requirements* | Controller & Chiller (Int) - 380-420 VAC, 3 PH, 50 Hz |

| Controller & Chiller (US) - 200-230 VAC, 3 PH, 60 Hz |

The above data is subject to change. All specifications are dependent on laser power, material type and thickness, and process platform - consult with a Preco associate.

* Laser Chiller may be powered separate or by laser system.

Medical Processing Equipment Line

Have Questions?

Reach out to a Preco sales representative directly to get your project started.

Equipment Sales

Jason Thoen

Salvatore Scarvaci