ST Series

Multi-Axis Laser Processing Machines

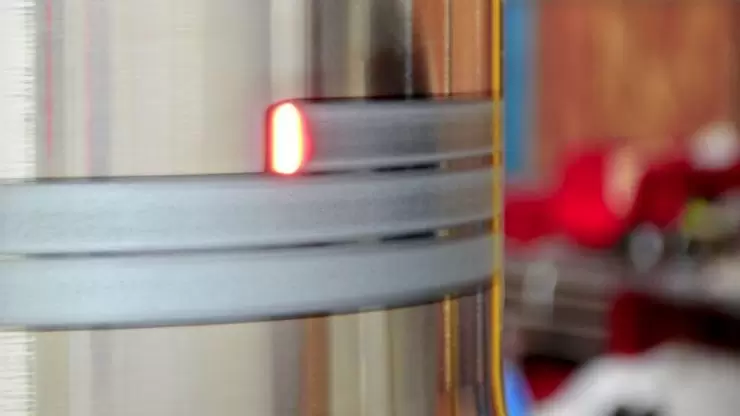

These workstations are designed for multi-axis laser welding, heat treating, cladding, drilling and cutting of metallic components.

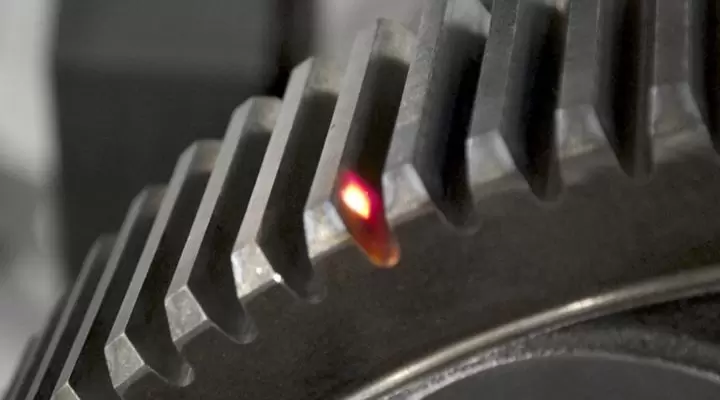

Laser heat treating is a surface modification process designed to change the microstructure of metals through controlled heating and cooling. Lasers offer an advantage in this process in the ability to heat treat localized areas without affecting the entire workpiece. During heat treating, the mass of the material being processed is generally sufficient for "self-quenching" for heat removal. One example of an ideal application of this technology is heat treating hand tools. No post-machining is needed in most situations.

Efficient and effective.

The enhanced mechanical properties resulting from laser heat treating depend upon the specific composition of the metal or alloy. For example, laser case-hardening of transformation-hardening metals provides high hardness and wear resistance with minimum distortion. In addition, laser spot annealing of precipitation and work-hardened metals (i.e., aluminum alloys and 300 series stainless steels) restores ductility and improves formability in critical areas.

Diode, Disk and Fiber lasers are commonly used for laser heat treating. These modern lasers have inherently high absorption properties allowing ease of use at a lower cost.

Some of the many advantages of Laser Heat Treating with a Preco-made machine.

In this webinar, you will see our practical, cut-to-the-chase discussion to discover insights about:

These workstations are designed for multi-axis laser welding, heat treating, cladding, drilling and cutting of metallic components.

The SL Series is manufactured from standard parts and integrated into a single workstation designed to fit specific customer needs.