Laser Services

Preco's Laser Contract Manufacturing Services can provide you with all of the resources needed to integrate laser cutting into your manufacturing stream. The extensive design, testing and manufacturing capabilities of Preco can help you answer today's challenges – enhancing product design, improving quality, lowering unit cost and shortening lead times.

PRECO IS A PROUD

A big facility with big possibilities.

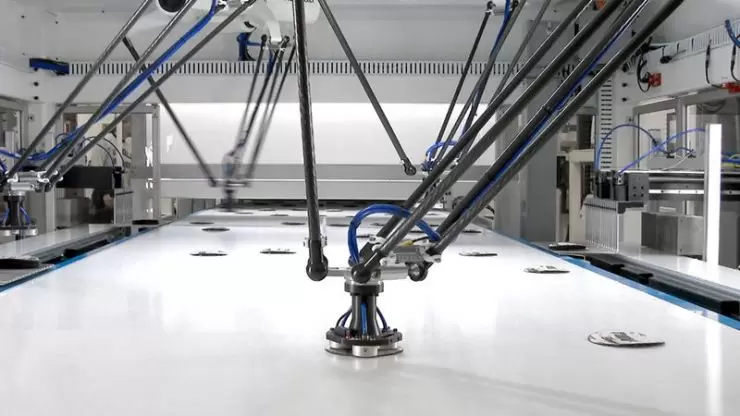

Complementing Preco's die cutting services, our Contract Manufacturing facility has over 40 laser workstations to help process your product.

The extensive design, testing, laser processing and manufacturing capabilities of Preco can help you answer today’s challenges – enhancing product design, improving quality, lowering unit cost and shortening lead times.

Capabilities

- 3 Clean Rooms

- 40+ Workstations

- Converting

- Flexible Packaging

- Metal Processing

- Medical Metals

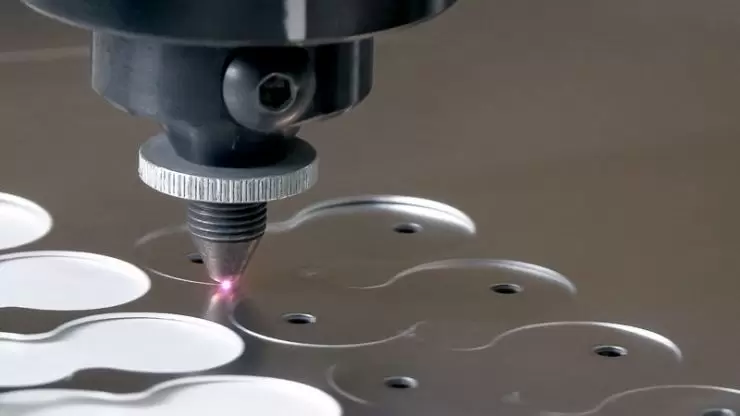

Abrasives

When it comes to production solutions for abrasive material processing, Preco Abrasives is the dominant market supplier. We handle it all, from wide-web processing of heavy grit abrasives through micro-polishing grits for glass or fiber-optic end connectors. Preco's die cutting and laser cutting technology is your advanced abrasive processing solution, with either purpose-built equipment for installation at your facility or toll converting using our suite of in-house production equipment.

Contract Services Offered

- Package, Shrink Wrap

and Label - Ship Complete to

Distribution Center

- Quality Testing

- Discs, Sheets and Rolls

- Laser Cutting

- Laser Marking

Flexible Packaging

Preco offers a complete range of flexible packaging laser enhancements including micro-perforations, easy-opening features and microwave venting. Preco's flexible packaging services include process development and toll converting to support your market introduction and long-term production requirements. In addition to a complete range of production roll handling systems, Preco also provides quality test equipment to provide stringent quality assurance protocols through your production run. Preco is certified to ISO 9001 and ISO 13485 quality management standards.

Contract Services Offered

- Laser Scoring – Easy Open

- Clean and Controlled Environment

- Laser Perforation – Micro-Perforation, Extended

Shelf Life

- Laser Microwave Venting

- Quality Testing

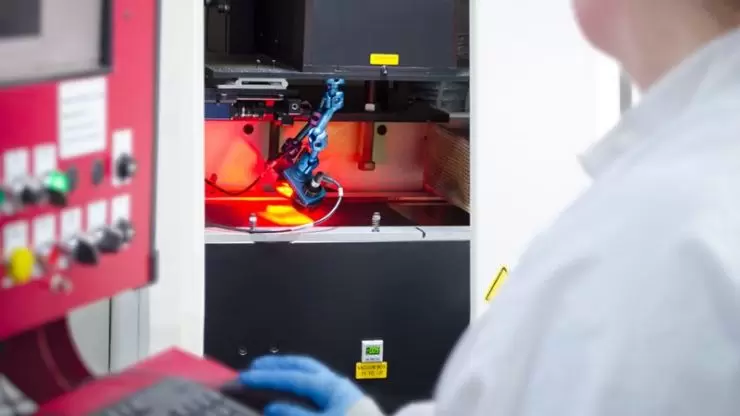

Metal Processing

Specializing in laser cladding, laser welding, laser heat treating and specialty laser cutting, Preco excels at difficult process-specific applications. With an in-house staff that includes welding engineers along with doctorate-level guidance, Preco's capabilities are unsurpassed. Our range of equipment includes fiber lasers up to 10kW and CO2 lasers up to 6kW which provide deep penetration welding and heat treating. Supporting this equipment are workstations and material handling that can support fabrications and castings weighing upwards of 10,000 pounds.

Contract Services Offered

- 12 Laser Workstations

- Fiber Delivered Lasers

Up to 10 kW - CO2 Lasers Up to 6 kW

- Material Handeling Capability Up to 10,000 lbs

- Blast Booth

- Assembly Presses

- Industrial Part Washer

- TIG and MIG Welders

- 200 KVA Spot Welders

Have Questions? Contact Us

Reach out to a Preco sales representative directly to get your project started.

Mark Daun

Joel Lombard

Wes Haney

Craig Swanson