Industrial Die Cutting Solutions

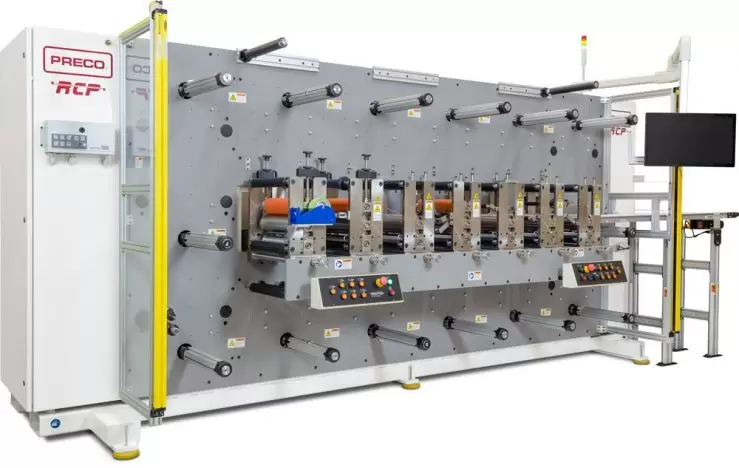

The Rotary Converting Platform is Preco's solution to your die cutting needs. Delivering the highest yields, production rates, flexibility and speed.

Contract Manufacturing Services

Complementing our laser converting offering, Preco's Rotary Die Cutting Contract Manufacturing Services also provides a complete range of die cutting solutions. Precision multiple station rotary die cutting for high productivity, lamination and rotary die cutting.

Common Rotary Materials

Just some of the many materials that Preco's Rotary Converting Platform (RCP) is capable of handling.

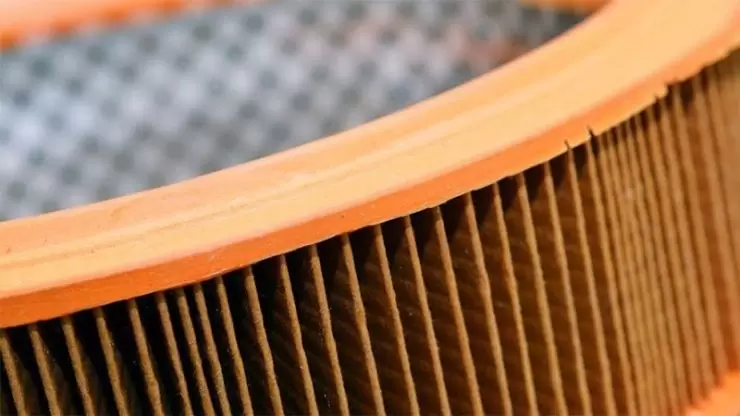

Gaskets

Everything from Rubber to Cork

Magnetic Media

From Cutting to Laminating

Pressure Sensitive Adhesives

PSA Cutting and Kiss-Cutting